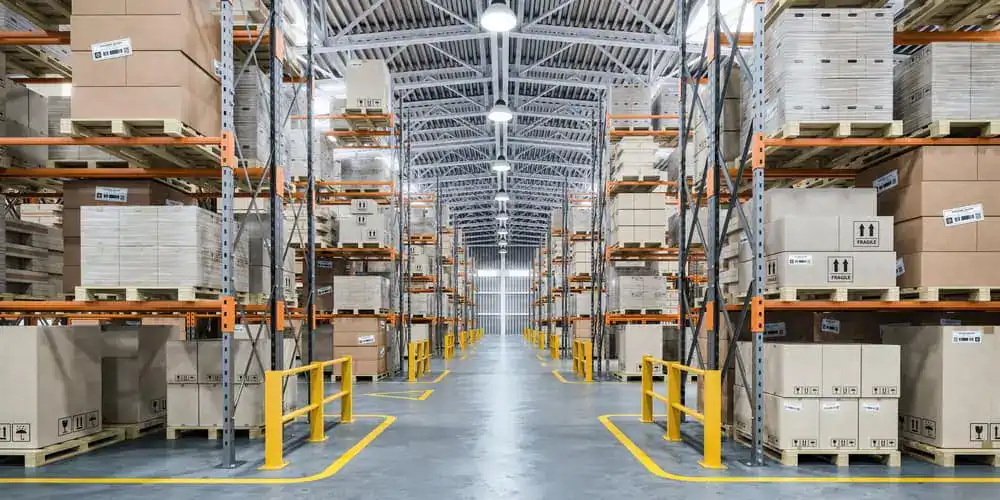

Supply Chain & Inventory Intelligence

Stop Flying Blind Through Your Inventory Operations

What is Supply Chain & Inventory Intelligence?

We transform your supply chain from a reactive cost center into a predictive competitive advantage. Our intelligent systems provide real-time visibility into inventory levels, supplier performance, and demand patterns while automating procurement, logistics coordination, and demand forecasting so your operations team can focus on strategic optimization instead of firefighting.

Stop reacting to stockouts, overstock situations, and supplier delays. Get the predictive intelligence and automated coordination you need to optimize costs, improve service levels, and turn your supply chain into a strategic advantage.

Logos featured belong to their respective brands and are used for identification purposes only.

You Need This If…

You discover stockouts after it’s too late.

Critical inventory shortages surprise you because tracking is manual and reactive. Lost sales, angry customers, and emergency rush orders that destroy your margins could all be prevented with proper visibility.

Warehouse space is wasted on dead inventory you forgot you had.

Without proper demand forecasting, you’re stuck with millions in slow-moving inventory taking up space while you rush-order items you actually need. Cash is tied up in products that don’t sell.

Supplier delays and logistics issues constantly disrupt your operations.

You find out about supplier problems when shipments are already late. Without automated supplier performance tracking and communication, you’re always reacting to disruptions instead of preventing them.

Demand planning is based on gut feeling and last year’s numbers.

Without predictive analytics, you’re either understocked and losing sales or overstocked and burning cash. Seasonal trends, market shifts, and growth patterns catch you off-guard because forecasting is manual guesswork.

For Companies Who Want More

What Your Next Quarter Could Be

Perfect Inventory Levels Without Constant Monitoring

Automated reorder points and demand-driven procurement that prevents stockouts while minimizing overstock. Your inventory turns faster, cash flow improves, and customers never experience shortages.

Supplier Issues Prevented Before They Impact Operations

Early warning systems that identify supplier risks, automated performance tracking, and intelligent backup supplier activation. Disruptions get resolved before they affect your customers or production schedules.

Accurate Demand Forecasting That Drives Strategic Decisions

Predictive analytics that account for seasonality, market trends, and growth patterns to optimize purchasing, staffing, and capacity planning. Make confident decisions based on data instead of guesswork.

Our Solution Arsenal

Build supply chain intelligence that scales with your growth – from basic inventory automation to advanced predictive analytics.

Intelligent Inventory Management

Automated inventory tracking, reorder point management, and demand-driven procurement optimization.

Supplier & Logistics Coordination

Automated supplier communication, performance tracking, and logistics optimization with real-time visibility.

Complete Supply Chain Intelligence Platform

End-to-end visibility and optimization from supplier management to customer delivery.

Advanced Analytics & Optimization Engine

AI-powered supply chain optimization that provides competitive advantages through superior forecasting and efficiency.

Your Implementation Timeline

Discovery & Assessment (Week 1)

We analyze your current processes and systems to identify specific automation opportunities and integration requirements.

Custom Solution Architecture (Weeks 2-4)

We design your tailored automation solution and create detailed implementation roadmaps with clear milestones and success metrics.

Build & Deploy Automation Systems (Weeks 5-11)

We build, test, and deploy your custom automation systems with seamless integration to your existing tools and workflows.

Performance Optimization & Ongoing Support (Weeks 12+)

We monitor results, fine-tune performance, and provide ongoing support to ensure maximum ROI and continuous improvement.

Timeline: 90-days or less for core transformation, with optimization and support continuing as your business grows.

Proven Operational Intelligence Expertise

OpenAI

Tier 5 Partner

Advanced AI implementation capabilities

Google AI Alpha Partner

Cutting-edge automation technologies

SpaCy

Contributors

Deep technical expertise in business intelligence

Trusted by: Professional services, manufacturing, financial services, and technology companies.

Implementation Power

We don’t just track inventory – we create intelligent supply chain ecosystems that adapt and optimize automatically.

Universal ERP Integration

For companies using any warehouse or inventory management system.

Custom integrations with SAP, Oracle, NetSuite, and 50+ ERP and WMS platforms. We enhance your existing systems with intelligence rather than requiring expensive replacements.

Industry-Specific Intelligence

For businesses with unique supply chain requirements.

Pre-built analytics and workflows for manufacturing, retail, distribution, and specialty industries. We understand the specific metrics, cycles, and challenges of your supply chain model.

Scalable Architecture

For growing companies with expanding operations.

Cloud-native platforms that scale from single locations to global operations. Add new warehouses, suppliers, and sales channels without rebuilding your intelligence infrastructure.

Guaranteed Visibility Improvement

For operations teams tired of supply chain surprises.

We guarantee real-time visibility into inventory levels, supplier performance, and demand patterns within 90 days. No more stockouts, overstock situations, or supplier surprises.

Ready to Stop Reacting to Supply Chain Chaos?

Get a free supply chain assessment where we’ll analyze your current inventory management, supplier coordination, and demand planning processes. We’ll identify the blind spots and inefficiencies that are costing you money and customer satisfaction. Most $2M+ companies reduce inventory costs by 15-25% while improving service levels.

No commitment required. Let’s show you where your supply chain intelligence gaps are costing you profit.